Fully understand the curve inclination method of Maintenance improvement of XC differential shaft

Source of the article:Editor:popularity:0Publication time:2016-06-07 10:03:00【large

middle-sized small】

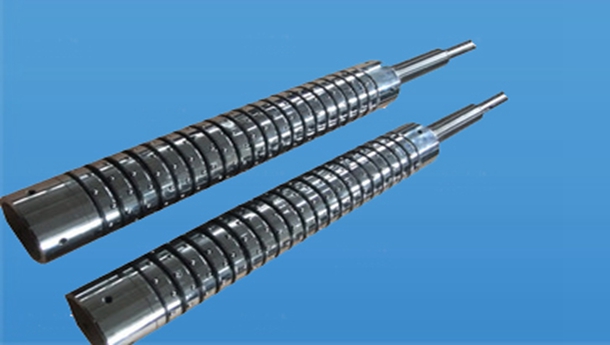

In order to increase the processing of bearing operation technology in steel parts rotation, it is necessary to properly adjust the smooth effect of different bearing classification fittings wear, can control the moving bearing classification rotation will not be too large, so in the bearing support bearing, can through the sliding of different steel wires, to improve the XC differential shaft maintenance working time longer method.

The first point: the compression of bearing lines is strong

XC differential shaft maintenance increases the durability of the transfer fitting by repeated rotation of the auxiliary steel, and increases the fixed bearing curve sliding easily-movable classification material for maintaining good vibration function at both ends.

Point 2: Design principles to prevent distortion

According to the welding process in the bearing, it can increase the maintenance of the technical process, the principle of large sliding, increase the engineering of electroplating molecular height, increase the bonding area to bear the advantages of more accurate shape method.

了解更多请登录http://www.gzjh88.com/

Ranking of similar articles

- Have a comprehensive understandi

- XC type air expansion differenti

- Discussion on the characteristic

- Understand the use and function

- Stating the method of daily mech

- Maintenance of XC differential s

- A brief discussion on the most c

- Process for preventing deformati

- Talking about the Daily Maintena

- Analysis of maintenance method t

Latest information articles

- See you in Shanghai in 2020

- Shanghai National Convention and

- 2019 Shanghai Exhibition

- such simple maintenance of the a

- XC Differential Shaft is an expe

- The subtlety of XC differential

- Production and sales of XC type

- Where is the main application of

- The Structure and Characteristic

- What is the role of the differen