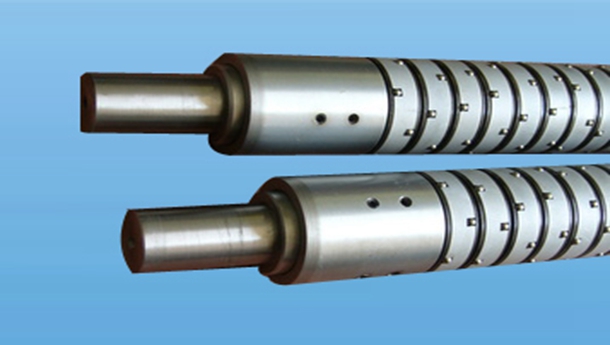

The method of maintaining and controlling the compression capacity of XC differential shaft without deviation

In the technical process of rotating steel, the rotating property generates the condition of friction rust, so under the control of the material rotating link, the shape of the steel with larger compression can be improved, and the effect of large conditioning area in the accessory supporting rotating delay process is satisfied.

Point 1: Flipping without flab

For in the operation of the rotary engineering, it is necessary in different precise position of the operating pressure, can avoid the whole process of sliding occurs force wear, so in the process of accessories to increase the sliding higher and faster speed adjustment.

The second point: to avoid the expansion of steel

The XC differential shaft maintenance can be adjusted according to the magnitude of the designed pressure in the steel moving process of the bearing force, so that the control center pressure of different main body steel is increased, and the effect of compression of fittings, special production process and large circulation is satisfied.

Ranking of similar articles

- Have a comprehensive understandi

- XC type air expansion differenti

- Discussion on the characteristic

- Understand the use and function

- Stating the method of daily mech

- Maintenance of XC differential s

- A brief discussion on the most c

- Process for preventing deformati

- Talking about the Daily Maintena

- Analysis of maintenance method t

Latest information articles

- See you in Shanghai in 2020

- Shanghai National Convention and

- 2019 Shanghai Exhibition

- such simple maintenance of the a

- XC Differential Shaft is an expe

- The subtlety of XC differential

- Production and sales of XC type

- Where is the main application of

- The Structure and Characteristic

- What is the role of the differen