Learn about the maintenance methods of air expansion shafts

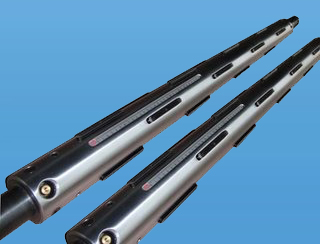

The air expansion shaft is also called pneumatic shaft, air expansion shaft, expansion shaft, etc. It is a special rewinding and unwinding shaft. After high-pressure inflation, the surface of the shaft can be protruding, and the surface part is quickly retracted after deflation. The more common accidents of air expansion shafts in work are mainly leakage. Once it leaks, it will not operate normally. Let's take a look at several possibilities of air expansion shaft leakage and how to repair them.

1. The hose is leaking. This phenomenon is that the quality of the hose itself is not good enough. After it is installed, it will leak if it has been inflated.

2. There is a gap in the sealing ring. Install the sealing ring and pour a ring of sealant on it.

3. The air nozzle is leaking and the air nozzle is not installed properly, just replace it with an air nozzle and install it.

4. The hose is broken. If this is the case, it will be troublesome. You need to remove the shaft head and replace it with a new hose.

Air expansion shaft use is extremely easy, user-owned air only, the air pressure is controlled at 6-8 within a range kg, locking the spool core when required, as long as the handle against the inflatable air expansion shaft air nozzle can be completed on a pneumatic , All machines and equipment used for rewinding and unwinding can be used with air expansion shafts.

Ranking of similar articles

- Talk about the function of XC di

- Understand the maintenance skill

- Talk about the effect of the lar

- How much is the maintenance of t

- XC differential shaft use: a pro

- What to do if the outside diamet

- The method of XC air expansion d

- The advantages of increased fric

- Fully understand the process of

- On the method of controlling spe

Latest information articles

- Talk about the function of XC di

- Understand the maintenance skill

- Talk about the effect of the lar

- How much is the maintenance of t

- XC differential shaft use: a pro

- What to do if the outside diamet

- The method of XC air expansion d

- The advantages of increased fric

- Fully understand the process of

- On the method of controlling spe