What parameters need to be provided for customized XC differential shaft?

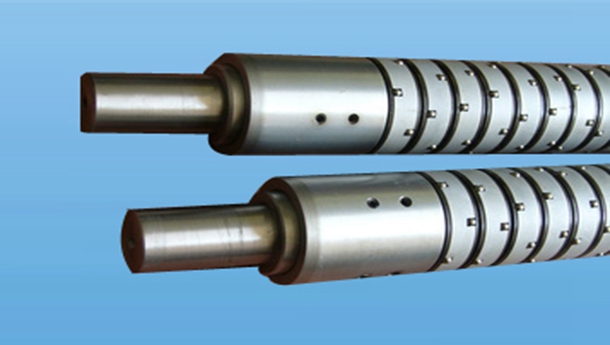

The customization of XC differential shaft is a relatively long process, so the parameters provided by the subscribers must be complete and accurate to avoid unnecessary losses. The following parameters need to be provided for customized XC differential shaft:

One: Type

According to the working principle, application field and other conditions, the differential shaft can be divided into many different types. The characteristic of

XC differential shaft is that it has the effect of segmented sliding;

Two: Dimensions and allowable deviations, material requirements

XC differential shaft has very strict requirements in terms of precision, so the size provided by the subscribers must be accurate, and it must be accurate to millimeters, microns or even more; the material of the differential shaft will directly affect its service life, of course There are different options for cost considerations. You can choose materials with higher cost performance;

Three: Quantity

The manufacturing process of the XC differential shaftis more complicated and requires a higher processing environment, so the production time will be longer. However, good things are always worth the wait.

Ranking of similar articles

- Talking about the XC differentia

- Understand the principle of infl

- Talking about the maintenance me

- Talking about the maintenance me

- How to repair XC air expansion d

- About the benefits of the high f

- Technical method for repairing p

- How the XC differential shaft ma

- Talking about how to clean the o

- XC differential shaft reduces du

Latest information articles

- Talking about the XC differentia

- Understand the principle of infl

- Talking about the maintenance me

- Talking about the maintenance me

- How to repair XC air expansion d

- About the benefits of the high f

- Technical method for repairing p

- How the XC differential shaft ma

- Talking about how to clean the o

- XC differential shaft reduces du