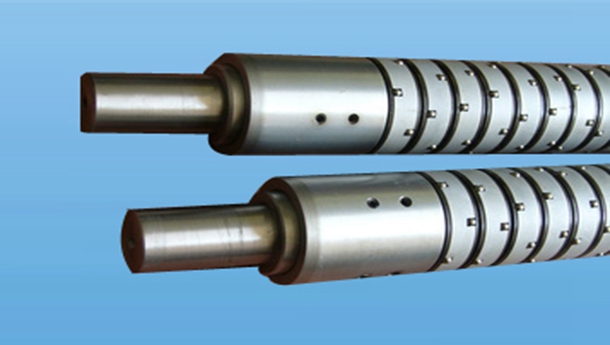

Technical method for repairing parts of XC air expansion differential shaft

Due to the rotatability of continuous industrial production, the inflexible rotation of the air expansion shaft will appear , so in the mechanical rotation control program, the effect of smooth sliding in the air expansion shaft accessories can be increased . Different plug-in or casing processes can increase the speed of rotation through the clutch rotation method. Below, let's take a look at the XC air expansiondifferential shaft !

First: Maintenance methods of CNC machine tools

In the turning control skills of the lathe, it is possible to increase the speed in the rotation process. For the bearing of the steel parts, it can also prevent the rust or unevenness of the steel from occurring. Flexible effect of mechanical rotation maintenance technology.

Second: accessories repair method

In the engineering of production technology, it is necessary to adjust the flat rate of steel rotation in time to avoid the situation that the machine is easy to cause damage. For machines that are rotating and grinding, the amount of rotation speed controlled must also be increased.

Third: Maintenance of casing lathe

In the production process of XC air expansiondifferential shaft, the production is carried out according to the productivity of the control machine, which improves the situation of no failure in the bearing control compression force, and timely adjusts the speed of the rotating machine.

Ranking of similar articles

- Talking about the XC differentia

- Understand the principle of infl

- Talking about the maintenance me

- Talking about the maintenance me

- How to repair XC air expansion d

- About the benefits of the high f

- Technical method for repairing p

- How the XC differential shaft ma

- Talking about how to clean the o

- XC differential shaft reduces du

Latest information articles

- Talking about the XC differentia

- Understand the principle of infl

- Talking about the maintenance me

- Talking about the maintenance me

- How to repair XC air expansion d

- About the benefits of the high f

- Technical method for repairing p

- How the XC differential shaft ma

- Talking about how to clean the o

- XC differential shaft reduces du